A Deep Dive into Metal Punching: Processes, Benefits, and Solutions

When fabricating sheet metal components, the chosen method for creating holes, slots, and complex openings is critical to the part's integrity, cost, and production schedule. For countless industries, the answer is often metal punching. This foundational fabrication process offers a powerful combination of speed, precision, and efficiency that other methods simply cannot match for certain applications.

We leverage state-of-the-art CNC turret punching equipment to deliver rapid, high-quality results. This deep dive will explore exactly what metal punching is, when it should be your fabrication method of choice, and how we master the process to ensure flawless components.

What is Metal Punching?

Metal punching is a high-speed forming process that uses a specialized machine press to create holes and shapes in sheet metal. It works on the principle of shear force, in which a hardened steel punch is forced through the sheet and into a corresponding die beneath the material.

The core components of the process are simple:

The Punch: The upper tool, which applies the force and determines the shape of the cut.

The Die: The lower tool, which supports the sheet metal and provides the necessary clearance for the punch.

The Press: The machine (often a CNC turret punch press) that provides the controlled, high-pressure force required for the shearing action.

When the punch descends, the material yields and shears, creating a clean, high-precision sheet-metal punch hole or a custom feature. The resulting waste material, known as the slug, is then automatically removed.

The Core Processes: Manual vs. CNC Punching

While simple manual presses exist for very small jobs, modern commercial metal fabrication relies on highly automated processes for speed and versatility.

CNC Turret Punching: Precision and Versatility

CNC (Computer Numerical Control) turret punching is the standard at HPM. These machines are equipped with a rotating turret that holds dozens of punches and dies, allowing rapid tool changes without operator intervention. This includes:

Complex Shapes: The turret holds standard shapes (rounds, squares, slots) as well as custom-formed tools, enabling complex features such as louvering, countersinks, and even minor forming operations.

High Speed: The combination of automated tool changes and rapid axis movement makes punching sheet metal faster than almost any other thermal or mechanical cutting method for high-volume jobs.

Progressive/Multi-Stage Punching

For extremely high volumes of small, complex parts, progressive punching is sometimes used. In this process, the metal (often in a coil) passes through multiple punch-and-die stations. Each station performs a single operation, and the final cut piece emerges fully formed after a continuous, multi-stage operation.

When to Choose Metal Punching: Key Benefits

Punching provides distinct advantages over alternative methods like laser cutting, especially when the following are prioritized:

1. Speed and Efficiency

CNC turret punch presses are extremely efficient. Once programmed, the machine can execute hundreds of hits per minute. For parts requiring numerous standard holes (sheet-metal punch-hole features), punching is significantly faster and less expensive per part than laser cutting. This directly translates into lower costs and faster turnaround for high-volume orders.

2. Cost-Effective Production

Punching is highly cost-effective in large runs. The operational costs are generally lower than those of laser cutting, and the process produces minimal scrap, leading to high material utilization. Furthermore, features such as tapped holes and light forming can be performed directly on the machine, minimizing the need for secondary operations.

3. Versatility and Material Range

Modern punching equipment can handle a wide variety of materials and thicknesses, including:

Steel (Cold-Rolled and Stainless)

Aluminum

Copper and Brass

Specialty Alloys

The turret can accommodate complex tooling, enabling features that would be difficult or impossible with a laser, such as:

Knockouts

Dimples

Logos

Custom Venting Patterns

4. Accuracy and Repeatability

CNC control guarantees high precision and repeatability. Once the program and tooling are set, every component in a batch will be punched identically, which is essential for welding assembly and maintaining tight tolerances in mass-produced items.

Mastering the Process: Workflow, Challenges, and HPM Solutions

Achieving consistent, high-quality metal punching requires skilled operation and effective process control. Our workflow and solutions address common fabrication challenges:

The General Workflow

Design & Program: Customer CAD files are analyzed for manufacturability (DFM) and translated into the machine program, optimizing tool sequencing and material usage.

Set Up: The appropriate tooling is loaded into the turret, and the material is accurately positioned.

Punching: The automated process begins, executing hundreds of hits quickly and accurately.

Unload: Final component removal is performed for integration into subsequent processes (such as bending, welding, etc.).

Inspect: Parts are checked against specifications.

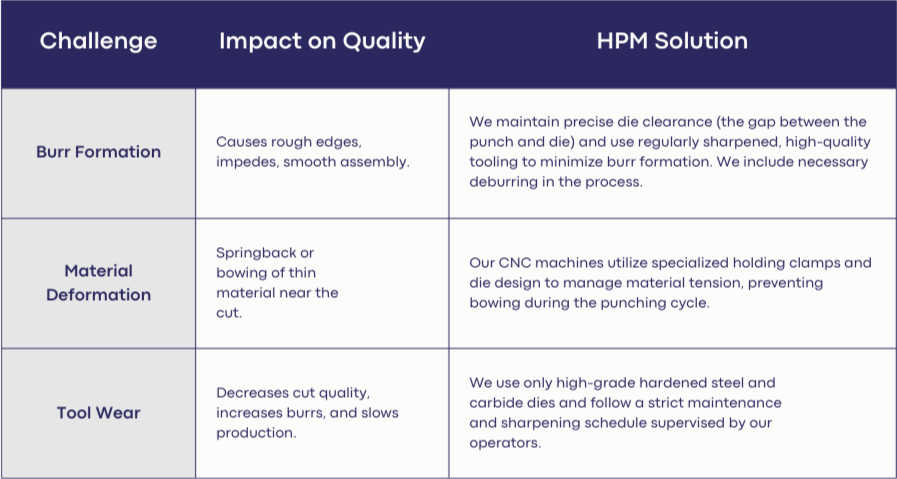

Addressing Common Challenges with HPM Solutions

Incorporate Punching Into Your Fabrication Process

Metal punching is a dynamic, efficient, and precise method that remains an indispensable technique in modern fabrication. When speed, consistency, and cost-effectiveness are your priorities for parts requiring numerous internal features, sheet metal punching is the definitive choice.

Partner with Herold Precision Metals to utilize our expertise and advanced turret punching capabilities. Request a quote for your next project today.