Engineering-Driven Metal Fabrication Services

Herold Precision Metals is more than just a fabrication shop. We’re a precision-focused partner that helps engineers and product teams turn concepts into manufacturable, scalable components. Whether you're starting with a napkin sketch, a 3D CAD file, or a finalized drawing package, our end-to-end fabrication engineering services help you move faster from design to production.

By getting involved early, we support smarter decisions around material choice, manufacturability, cost, and downstream assembly. With over 110,000 square feet of high-tech manufacturing space, our facility is designed to meet the needs of both agile startups and mature OEMs. From prototyping to production, we help you build better parts faster.

Support Across the Full Product Lifecycle

-

New Product Introduction

Accelerate your go-to-market timeline with structured product launch support. Our team helps validate manufacturability, plan for production, and streamline onboarding for repeat orders.

-

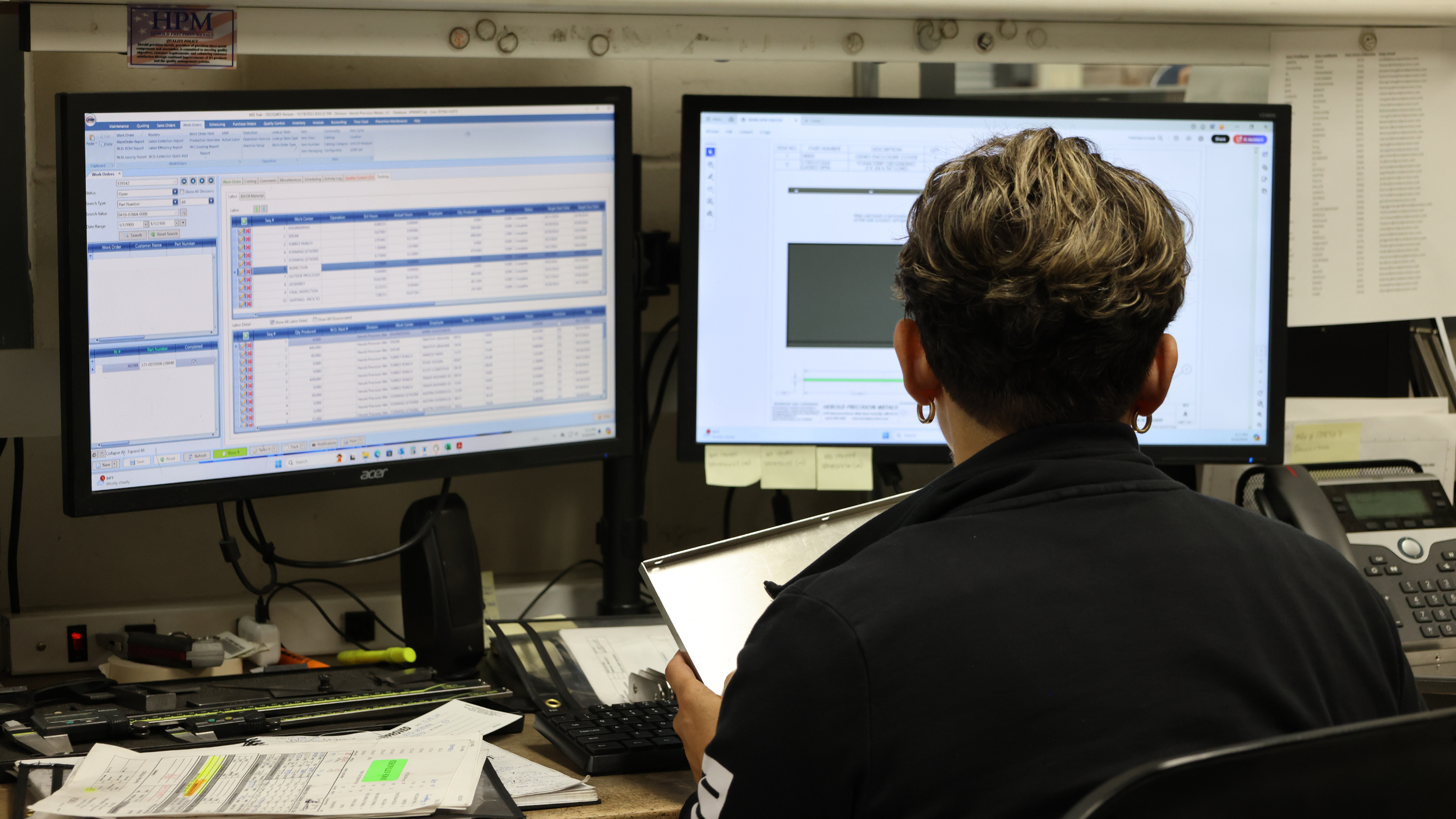

Estimating

Receive fast, accurate cost projections and lead time estimates based on real manufacturing inputs, not guesswork. Our quoting team works directly with engineering and purchasing.

-

Early Design Consultation

Need a second set of eyes on your design? Our engineers offer DFM input to reduce complexity, improve part performance, and eliminate costly revisions downstream.

-

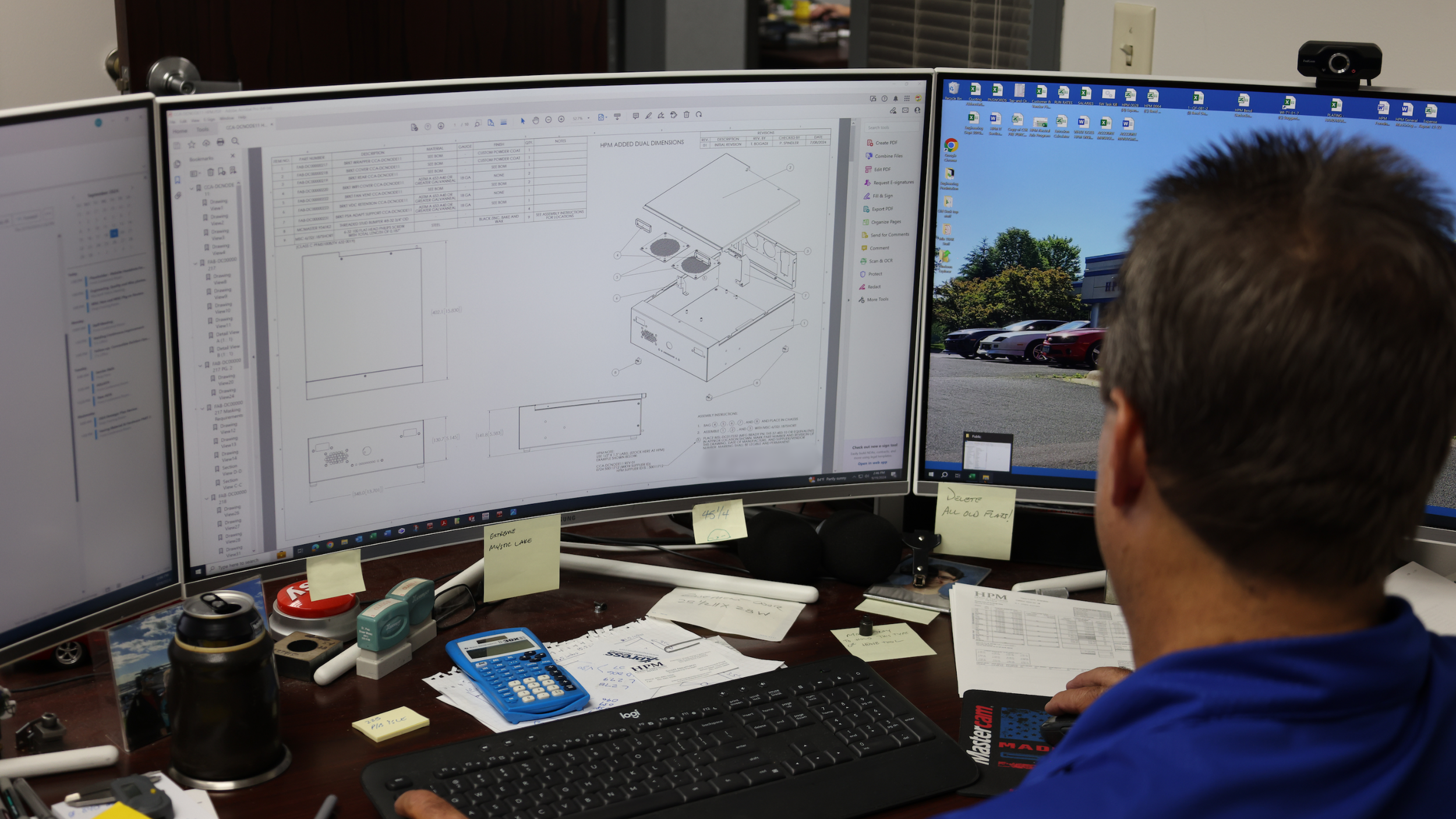

Engineering Support

Leverage advanced CAD/CAM software, simulation tools, and material expertise to refine your parts before fabrication. We're fluent in interpreting 2D and 3D files, from concept models to production drawings.

-

Project Management

From multi-component builds to serialized production runs, our project managers ensure that communication flows smoothly and timelines remain on track. You’ll get proactive updates without surprises.

-

Account Management

Dedicated account managers provide a single point of contact who understands your technical, logistical, and timeline needs, especially valuable during fast-paced development cycles.

-

Prototype

Quick-turn prototyping services help your team iterate faster and validate functionality before full production. We support the development of sheet metal and electromechanical prototypes.

-

Pre-Production

Bridge the gap between prototyping and scale with pre-production testing, documentation, and workflow setup. Ideal for regulated industries or projects requiring FAIR documentation.

-

Quality Assurance

Every component is validated through rigorous quality processes. We are ISO 9001:2015 certified, ITAR registered, and RoHS compliant. With FAIRs, PPAP, and an in-house CWI, we support your traceability and compliance needs from first article to final inspection.

What You Can Build With Our Engineering Services

Our fabrication engineering team supports a wide range of part types, from simple brackets to complex multi-component enclosures. Whether you're building work-in-progress assemblies or polished, customer-facing housings, we help engineer solutions that meet your performance, cost, and quality targets.

Common deliverables include:

Chassis and enclosures

Precision panels and flanges

Mounting brackets and faceplates

Mechanical subassemblies

Rapid prototypes for concept validation

Finished parts with hardware, coatings, or wiring

Materials We Engineer For

Our team works with a wide variety of metals, from standard sheet steels to advanced alloys and pre-finished materials. We help you choose the right material based on strength, weight, corrosion resistance, or formability. Common materials include:

Aluminized Steel

Type 1, Type 2

High Strength Steel

Grade 50, Grade 80, 4130, 4140

Spring Steel

Stainless Steel

304, 301, 430, 316, 316L

Aluminum

5052, 6061, 3003

Pre-anodized Aluminum

Copper

Carbon Steel

1018, 1008, A36

Galvanized Steel

G30, G60, G90

Galvanneal Steel

A40, A60

Brass

Pre-painted Steel

Pre-Painted Aluminum

Industries We Support

Our fabrication engineering services are trusted by teams across high-spec, highly regulated, and design-driven industries.

Built for Engineering Teams

Whether you're launching a new product or refining an existing one, HPM delivers the fabrication engineering services that help your parts perform and your team succeed. Request a quote today to get started with:

Collaborative quoting and design reviews

DFM support for manufacturability and cost optimization

Support for FAIR, PPAP, and other regulated documentation

Tight tolerance fabrication with integrated quality checks

Flexible volume options from prototypes to production