AWS Certified Welding & Fabrication: MIG, TIG, and Robotic Solutions

When your project demands guaranteed structural integrity, Herold Precision Metals delivers certified welding and fabrication services backed by rigorous quality standards. We offer advanced welding solutions, including manual MIG welding, precision TIG welding, and consistent robotic welding, ensuring every assembly meets the highest industry and military welding requirements.

Advanced Welding Solutions & Equipment

HPM’s state-of-the-art facilities feature flexible welding cells, including advanced manual stations and automated systems. We offer cosmetic finishing services to deliver products that meet both functional and aesthetic requirements.

MIG Welding: Speed and Strength

Metal Inert Gas (MIG) welding is ideal for producing high-quality welds at a faster rate, making it suitable for heavy-duty manufacturing and high-volume production. Our services are perfect for projects that require speed without compromising on strength or durability.

TIG Welding: Precision and Control

Tungsten Inert Gas (TIG) welding offers superior precision and control, making it the go-to method for applications that require intricate welds on thinner materials or specialized alloys. Our expertise delivers clean, strong welds that meet the stringent requirements of industries such as aerospace and medical device manufacturing.

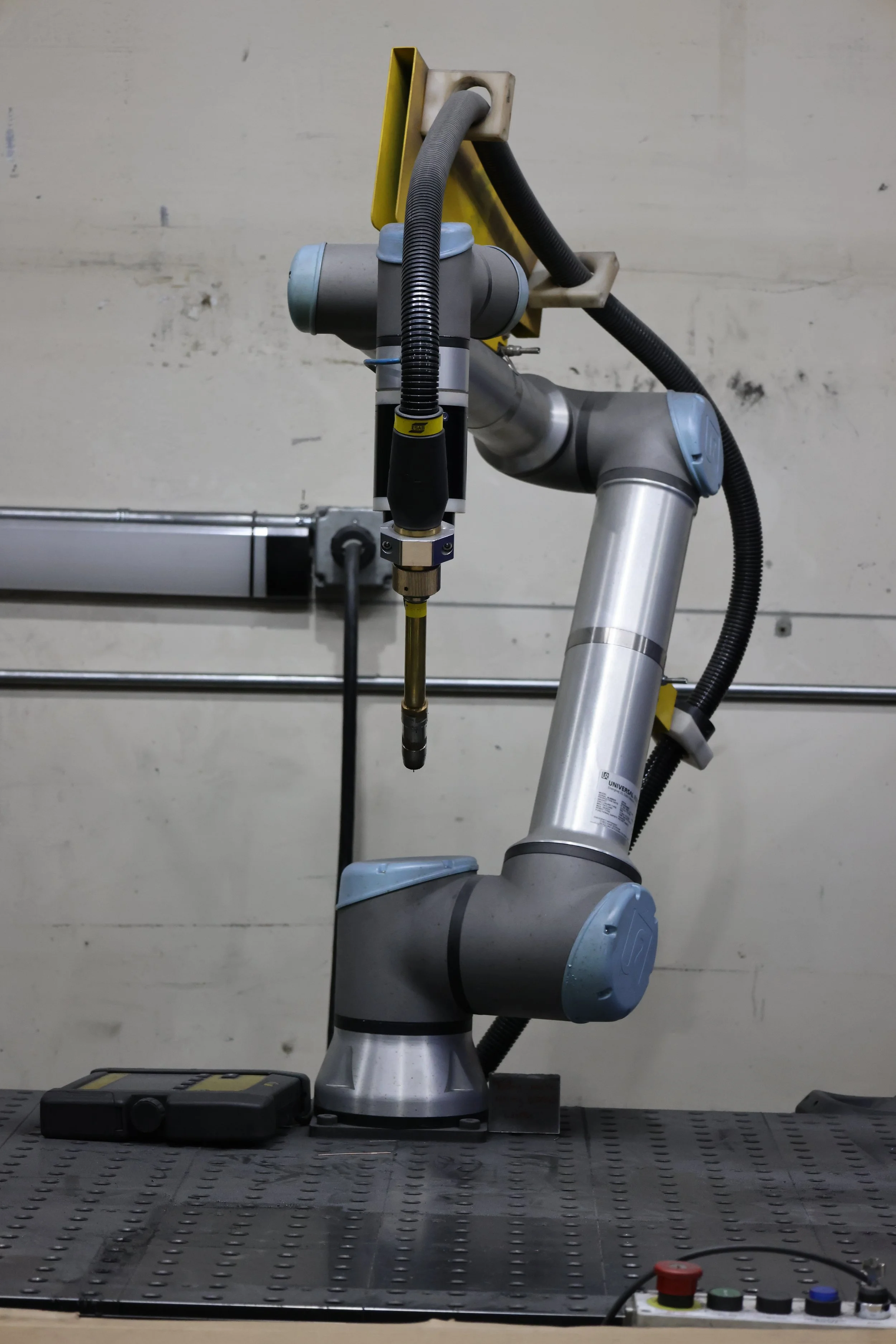

Robotic Welding: Consistency and Repeatability

Our robotic welding services bring unparalleled consistency and efficiency to high-volume production and complex assemblies. By utilizing automated systems, we achieve precise, repeatable welds that meet the exacting standards of industries where reliability is non-negotiable.

Engineered Custom Fixtures for Welding Assembly

Each welded project requires analysis and potential fixturing. Our experienced engineers and welders collaborate efficiently to design and manufacture custom fixtures for your specific project, ensuring part alignment and maintaining tolerances throughout the welding process.

Our Commitment to Certified Welding Quality and Compliance

Our certifications are a commitment to delivering repeatable, verifiable quality. We have the following weld certifications, supported by in-house Certified Welding Inspectors, showing our commitment to excellence and continuing growth in this discipline.

-

AWS D1.1 (Structural Steel)

Certified to meet the structural welding code for steel to support critical infrastructure and heavy-duty applications.

-

AWS D1.2 (Aluminum)

Certified under the aluminum welding code to produce strong, reliable welds in aluminum, essential for lightweight and corrosion-resistant applications.

-

AWS D1.3 (Sheet Steel)

Certified for sheet steel welding to produce durable welds on thinner materials often used in general sheet metal manufacturing.

-

ISO 9001:2015

HPM's commitment to quality is reinforced by our ISO 9001:2015 certification, which covers our fabrication of precision sheet metal components and assemblies and demonstrates that our processes meet international standards for quality management.

-

ITAR Registration

Registered with the U.S. Department of State under the International Traffic in Arms Regulations (ITAR), we are authorized to handle and manufacture sensitive defense-related articles, ensuring compliance with all necessary regulations for military welding.

Military and Defense Ready Welding Capabilities

HPM is equipped to meet the stringent demands of military welding projects. Our ITAR registration, deep experience, and compliance with military standards enable us to manage sensitive defense-related fabrication and welding tasks. You'll get assurance that all products meet the rigorous requirements for durability, precision, and performance in critical applications.

Other Industries Reliant on HPM's Certified Welding

We serve a diverse array of markets that rely on our certified welding processes to ensure the structural integrity and long-term performance of their components.

FAQs: Certified Welding Explained

-

It means our facility, procedures, and personnel adhere to the standards published by the American Welding Society (AWS), guaranteeing the quality and compliance of our structural welds across different materials.

-

Robotic welding services are ideal for high-volume orders with consistent geometry. It eliminates human variability, delivering faster cycle times, lower costs, and unparalleled repeatability for every welding assembly.

-

A Certified Welding Inspector (CWI) verifies that all welding procedures and welders meet the required codes and standards. They perform visual inspections and oversee testing to ensure the finished welds meet critical performance and quality requirements.

Learn More About Welding

Explore our expert resources to understand how different metal joining methods and quality control measures impact the strength, integrity, and cost of your fabricated assemblies.

-

Riveting vs. Welding: Choosing the Right Metal Joining Method

An essential comparison of two permanent joining techniques, detailing when certified welding is the superior choice for load-bearing and structural applications, versus when riveting offers assembly advantages.

-

MIG vs. TIG Welding: Understanding Both Processes

A detailed guide comparing the speed and high-volume capability of MIG welding with the precision and aesthetic quality of TIG welding, helping you choose the right process for your specific material and structural needs.

-

Advantages Of Having A CWI On Staff At Our Fabrication Shop

Understand the critical role of a Certified Welding Inspector (CWI) in ensuring code compliance, weld quality, and the overall integrity of your certified welding and fabrication projects before they leave our facility.

Request A Welding Quote

Ready to work together on your next welding project? Contact us to learn how our welding and fabrication services can meet your needs.