Uncompromising Quality Assurance for Metal Fabrication

Quality is more than a checkpoint — it’s a discipline woven into every step of our production process. Backed by ISO 9001:2015 certification, our fabrication quality assurance (QA) program supports industries that demand performance, traceability, and compliance. From rapid prototyping to full-scale production, our goal is to deliver parts that meet or exceed your specifications every time.

Manufacturing Quality Assurance

Our sophisticated quality assurance program, certified to ISO 9001:2015 standards, ensures that we uphold the highest levels of manufacturing quality. Key aspects include:

Rigorous Inspection and Testing: Every stage of production undergoes thorough inspection and testing for precision and reliability.

Advanced Measurement Equipment: We use state-of-the-art measurement equipment and calibration procedures to verify accuracy.

Strict Process Controls and Documentation: Detailed process controls and documentation support consistent quality and traceability.

Continuous Improvement: We implement continuous improvement initiatives to enhance our quality systems and adapt to evolving standards.

Our quality management system is designed to support consistency, compliance, and confidence across every project. HPM holds the following certifications and compliance standards:

Certified Quality Systems You Can Trust

ISO 9001:2015 Certified

Our QMS meets international quality standards for process control and continual improvement.

ITAR Registered

We maintain eligibility to handle regulated defense-related projects.

RoHS Compliant

All products meet environmental safety standards because we comply with the Restriction of Hazardous Substances directive.

UL Certified

All products meet rigorous safety and quality standards as verified by Underwriters Laboratories (UL) certification.

Primary QA Concepts

We use a combination of high-precision tools, statistical methods, and procedural discipline to uphold our quality standards throughout the entire fabrication cycle. Our approach includes:

Customized Documentation: Provide customized documentation tailored to your specific requirements, in collaboration with your engineering and inspection teams, to optimize technology use and enhance throughput without compromising quality. Our case studies demonstrate significant time and cost savings, often integrated into the New Product Introduction (NPI) process, accelerating product launches with confidence.

PPAP (Production Part Approval Process): Confirms that newly designed or revised parts can be fabricated consistently and within tolerance to meet your specifications and production methods.

Material & Finish Certifications: Ensures traceability and compliance with customer, environmental, or industry-specific standards.

Cpk Studies (Process Capability Index): Evaluates process repeatability and statistical performance relative to customer-specified tolerances.

FAIR (First Article Inspection Reports): Verifies that the part, process, and production setup meet design requirements before release to production.

Quality Control Plan (QCP): Identifies potential failure points and outlines proactive controls to prevent errors.

Quality Assurance Process

ISO Adherence

ITAR Compliance (when applicable)

Timely, technical and proactive review of project requirements.

Measurement and documentation design

Data collection and documentation population

Data review, observations and document submission.

Ongoing Audits and documentation

What It’s Like to Work With HPM

When you partner with Herold Precision Metals, you’re gaining more than a part supplier. You’re working with a team that collaborates with your engineers, understands your specifications, and builds trust through documentation, communication, and delivery.

From technical kickoff meetings to final audits, we align with your internal QA expectations to minimize rework, accelerate time to production, and support long-term success.

Frequently Asked Questions About Manufacturing Quality Assurance

-

FAIR stands for First Article Inspection Report. It verifies that a part and its production process meet all engineering drawings and specification requirements before moving to full production.

-

PPAP, or Production Part Approval Process, is a standardized approach to confirming that a manufacturer can consistently produce parts that meet customer requirements. It's especially important in regulated and high-risk industries.

-

Cpk (Process Capability Index) is a statistical measure that compares how well a manufacturing process can meet specification limits. A higher Cpk value indicates greater process capability and consistency.

-

Yes. HPM is ISO 9001:2015 certified, which means we follow internationally recognized standards for quality management and continuous improvement.

-

Absolutely. We collaborate with engineering and inspection teams to generate tailored documentation, including FAIRs, PPAPs, and material certifications, aligned to your project’s needs.

Learn More About Quality Assurance

-

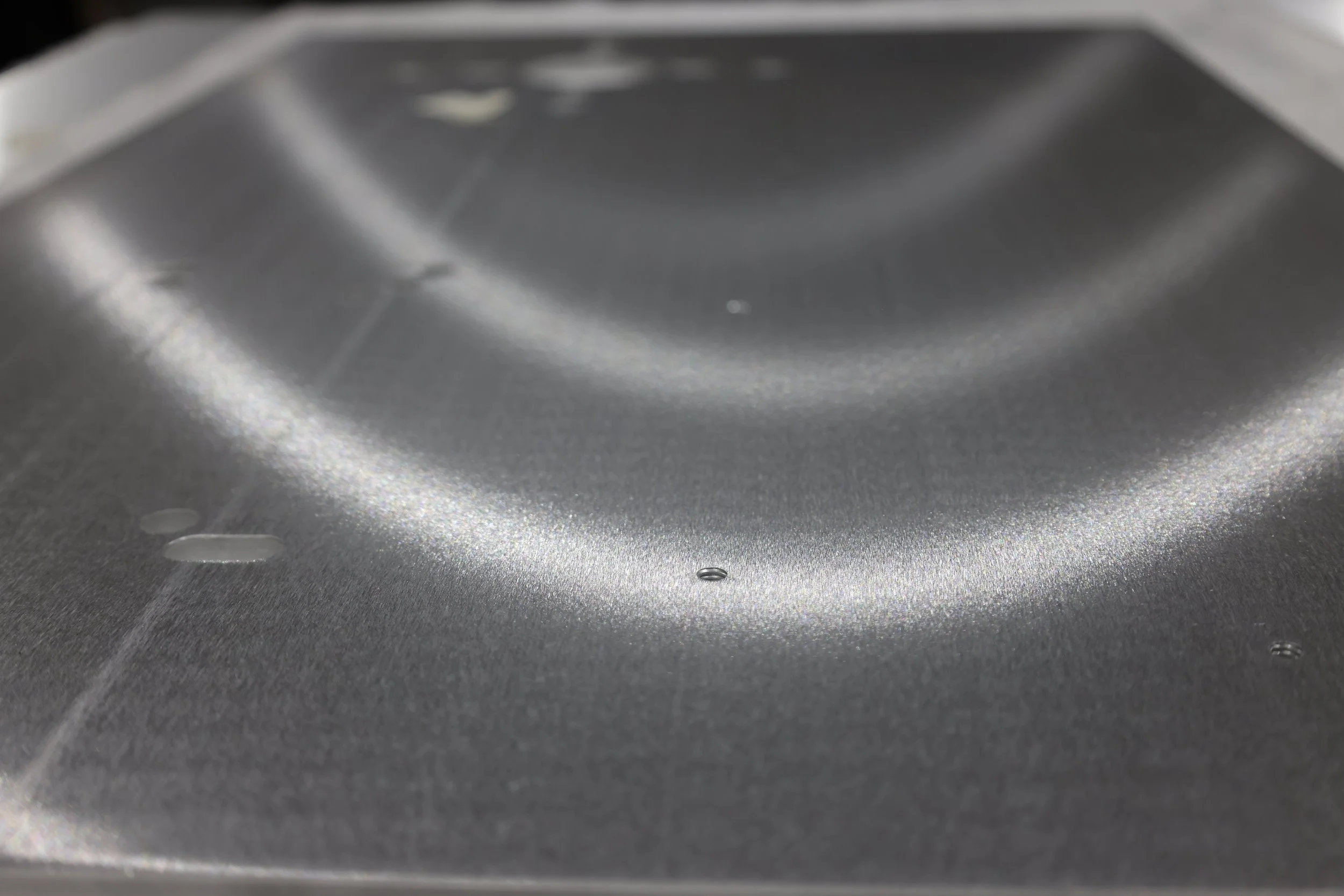

Laser Inspection for Sheet Metal: How It Works & Why It Matters

Learn the fundamentals of laser scanner inspection, how the Virtek LaserQC works, and why it plays a critical role in verifying flat part accuracy.

-

Automate Your Flat Part Inspection and FAIR Documentation

Explore how automation improves speed, accuracy, and traceability in first article inspection reports, which are especially useful for regulated industries.

-

Sheet Metal 101: Essential Terms & Concepts Every Engineer Should Know

Get up to speed on key terminology used in quality, fabrication, and inspection so you can communicate effectively with manufacturers.