Precision Metal Machining Services & CNC Solutions

When standard fabrication limits are reached, you need precision metal machining to achieve the exact fit, finish, and performance your application requires. Whether you are working with tight tolerances or need secondary metal machining services to finalize a fabricated build, we provide the technical expertise to get your project ready for the line.

Our In-House Machining Equipment

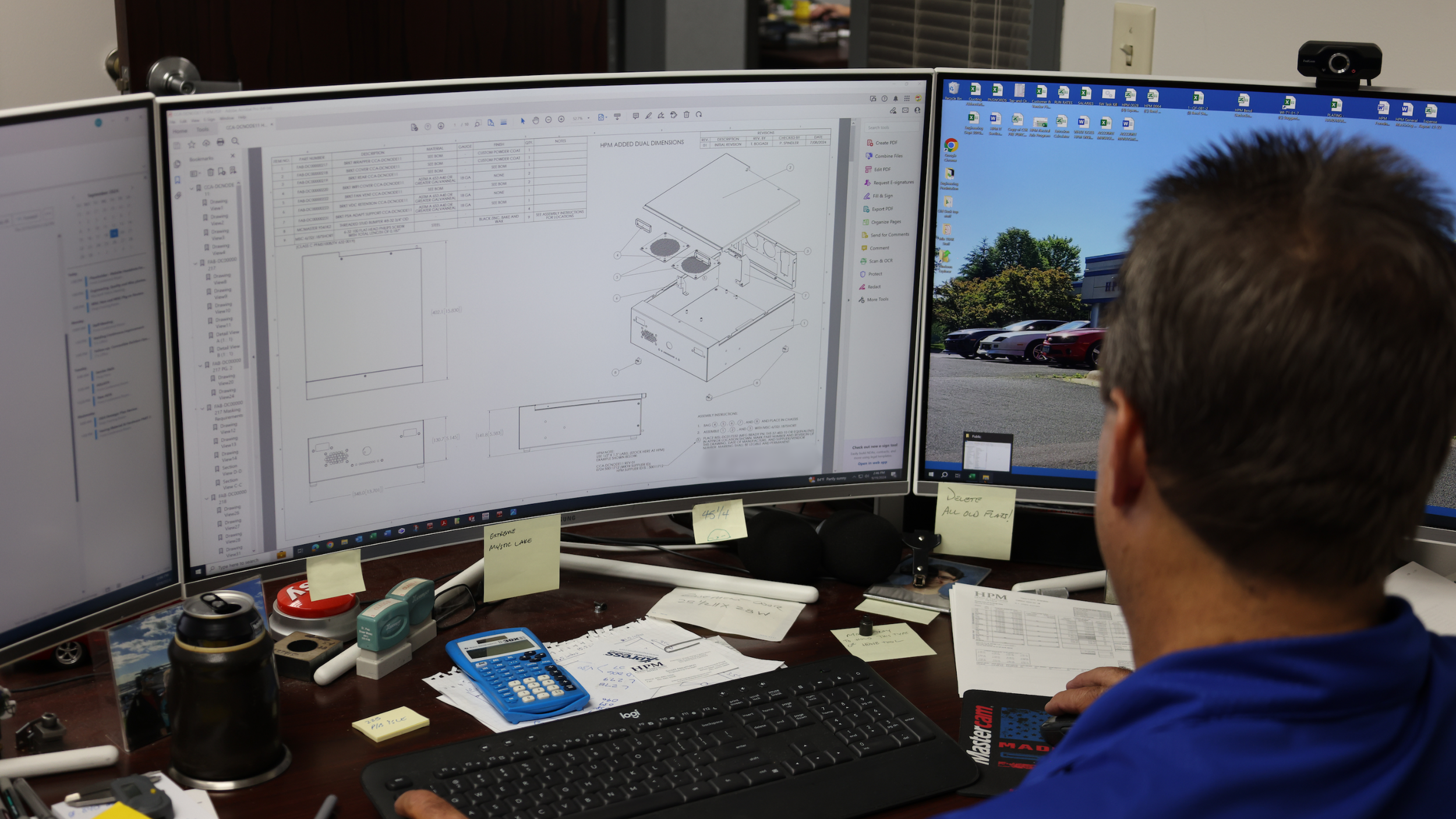

HPM’s machining department is equipped to handle everything from rapid prototyping to high-volume steel machining. We use a mix of manual and CNC equipment to meet tight tolerances and complex geometries.

-

High-precision automated milling for complex parts

-

Programmable milling for consistent, repeatable results

-

Versatile manual milling for custom features and fixtures

-

Precision turning for cylindrical components and hardware

-

High-torque drilling for heavy-duty applications

-

Precision drilling for specialized hole patterns

Why Choose HPM for Machining?

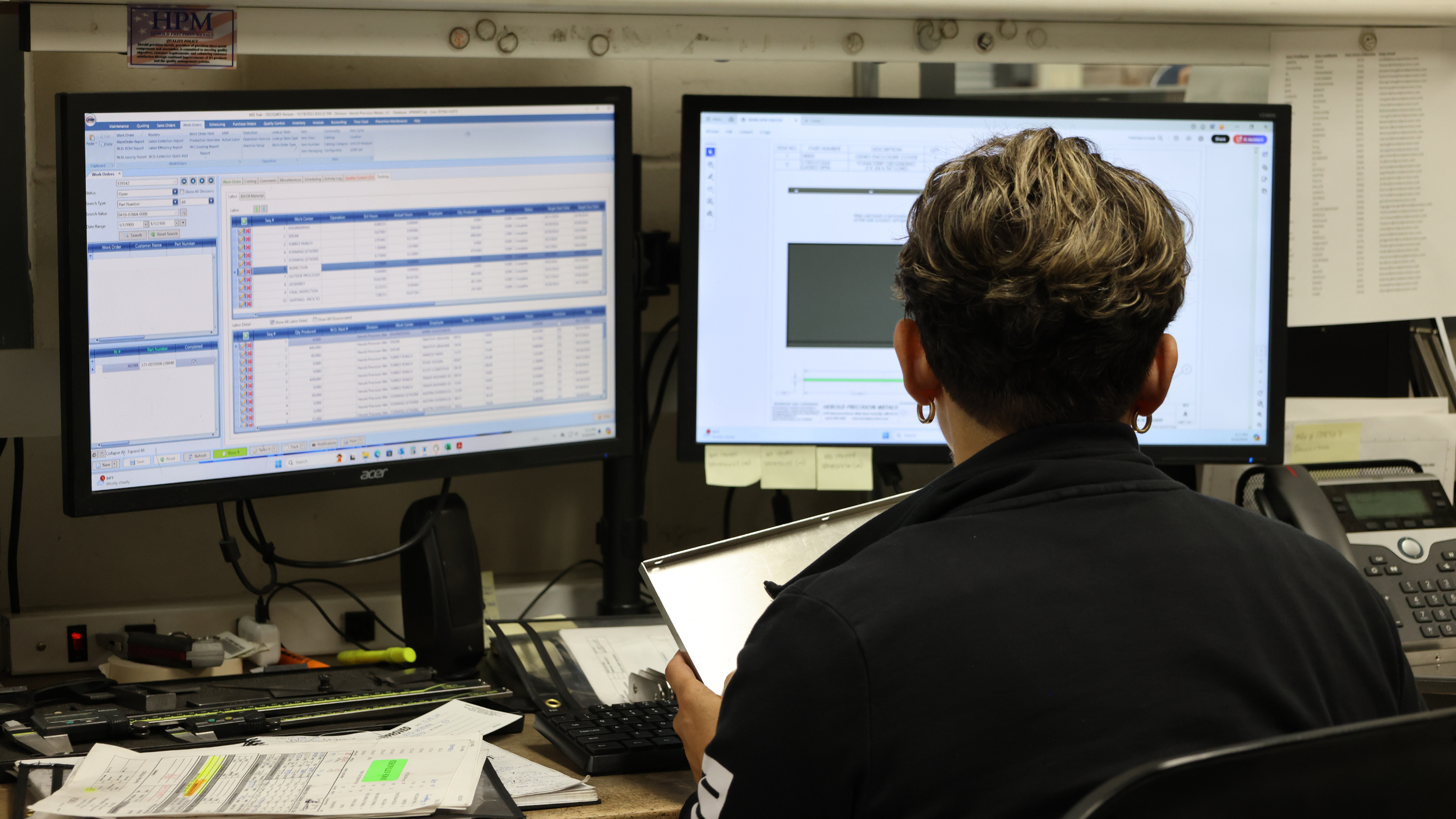

Choosing HPM means your parts are handled by a team that understands the intersection of machining and sheet metal. This integrated approach reduces lead times and eliminates communication errors that often occur when working with multiple vendors.

Integrated Fabrication: We specialize in sheet metal machining, performing secondary operations like precision boring, facing, and milling on fabricated parts to ensure perfect fitment in complex assemblies.

Custom Fixture Design: We design and build our own inspection and welding fixtures in-house, ensuring every project, even those with complex geometries, remains within tolerance.

Material Expertise: Our team has extensive experience in steel machining and in working with aluminum, stainless steel, and specialized alloys.

Prototyping to Production: Our Tool Room environment allows us to move quickly from a single prototype to a full-scale production run without sacrificing precision.

Common Applications for Metal Machining

Precision machining is essential for components that require tighter tolerances than standard sheet metal forming can provide.

Custom Tooling & Fixtures: Developing high-accuracy fixtures to hold tolerances during welding and assembly.

Precision Mounting Points: Machining thick plates or blocks that are integrated into larger sheet metal enclosures.

Bushed Holes & Reaming: Ensuring perfectly round, smooth holes for high-performance mechanical interfaces.

Prototyping & DFM: Using our machining centers to validate Design for Manufacturability (DFM) before committing to large-scale production.

Industries HPM Serves

HPM serves a diverse array of markets, providing tailored solutions to meet the unique needs of each industry. From military and data centers to electronics and consumer goods, we leverage our metal machining expertise to deliver high-quality products and services that exceed expectations across various sectors, ensuring every machined component meets the rigorous standards of our global partners.

FAQs: Metal Machining Services Explained

-

Fabrication typically involves cutting, bending, and welding sheet metal. Metal machining is a subtractive process in which material is removed from a solid block or fabricated part using tools such as mills and lathes to achieve extremely tight tolerances.

-

Yes. This is one of our specialties. We often perform sheet metal machining on welded assemblies to ensure that critical mounting surfaces are perfectly flat and holes are precisely aligned.

-

While tolerances depend on material and geometry, our CNC 3-axis milling center allows us to hold much tighter tolerances (often within +/- .001") compared to standard sheet metal tolerances.

-

Absolutely. We have the equipment and tooling specifically designed for steel machining, including hardened steels and stainless steel alloys commonly used in military and industrial applications.

Learn More About Integrated Machining

Discover how machining complements our other capabilities to create a complete manufacturing solution.

-

Sheet Metal Tolerances Explained: Achieving Precision in Fabrication

Discover how precision metal machining extends fabrication beyond standard limits, enabling the extreme accuracy required for high-performance assemblies.

-

Design for Manufacturability: Adding Value & Reducing Costs

Learn how integrating metal machining during the design phase can simplify complex geometries and reduce the total cost of ownership for your parts.

-

We Think Like a Tier 1 Manufacturing Vendor Even If We’re Tier 2 in the Supply Chain

See how our investment in CNC milling centers and quality-first machining reflects a Tier 1 mindset that ensures your supply chain remains robust and predictable.

Partner With Us For Your Metal Machining Needs

Maximize the potential of your fabrication projects by integrating our machining services. Whether you’re looking to enhance an existing process or need a complete solution, HPM provides the expertise and equipment to achieve exceptional results. Request a quote today to learn how HPM's metal machining services can bring precision and quality to your next project.