High-Precision Sheet Metal Laser Cutting Services

HPM specializes in precision sheet-metal laser cutting, delivering tight tolerances, clean edges, and complex geometries with speed and accuracy. Our high-powered fiber lasers and automated material handling systems make us the go-to fabrication partner for customers who need scalable, repeatable results.

Our Laser Cutting Machines & Technology

We cut metal and lead times. Our laser systems combine high-power fiber optics, automation, and real-time quality monitoring to keep production moving 24/7.

1 Mitsubishi 10,000 KW ML3015GX-F100(D)

1 Mitsubishi 8,000 KW EX-F Zoom Series

1 Mitsubishi 8,000 KW EX-F Zoom Series

1 Amada 2500 KW LC1212 XL Deluxe

1 Amada 2000 KW 1212 XL Deluxe

Laser Cutting Machines

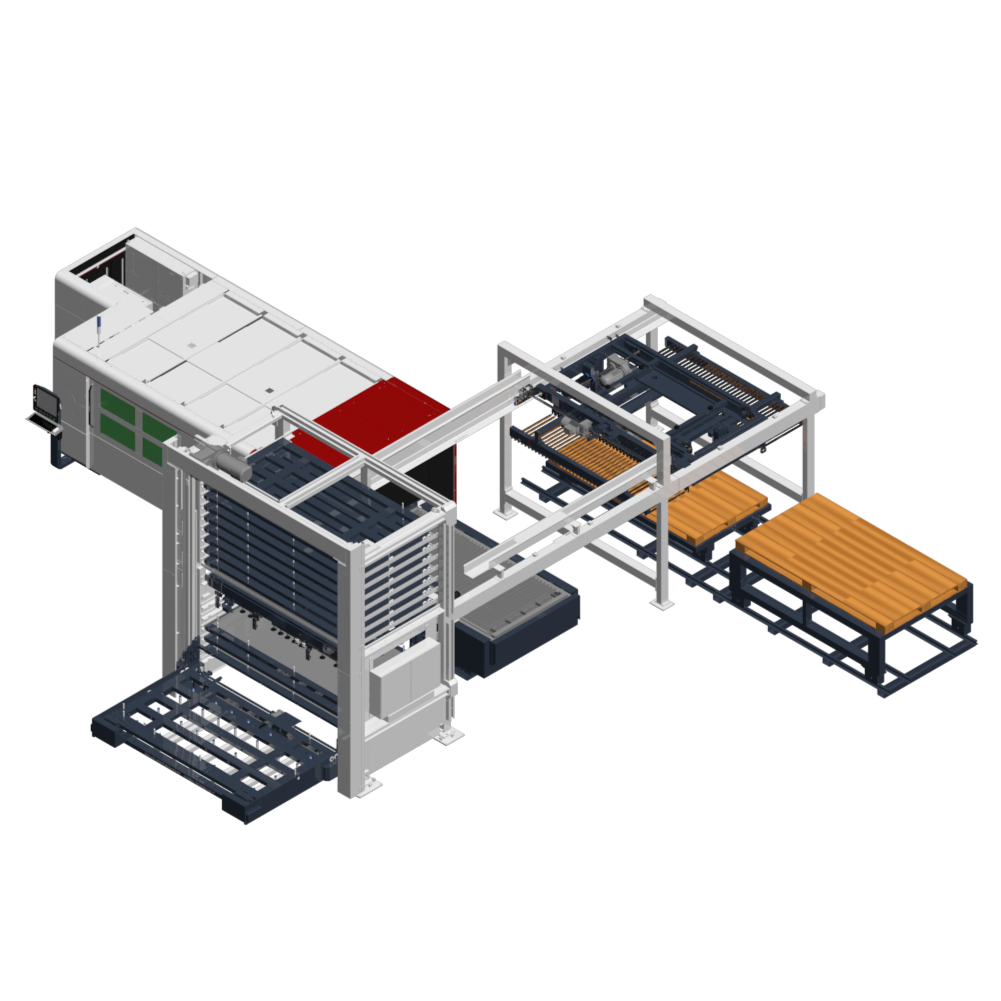

Flexible Manufacturing System Automation

Three of our Mitsubishi laser cutting systems are fully integrated with FMS automation, automated towers that handle raw material loading, cutting, and unloading with minimal human intervention. This allows us to run complex jobs overnight or through weekends while maintaining consistent output. With AI-driven monitoring and part verification, you get repeatable results, reduced rework and waste, and faster turnaround times.

Why Choose HPM’s Laser Cutting Services?

Whether you're looking for precision in intricate designs or efficiency in high-volume production, our laser-cutting capabilities are designed to meet your needs. We combine advanced technology and experienced craftsmanship to deliver results that exceed expectations.

24/7 Lights-Out Operation: Our SMARTFLEX RAPID TOWER systems allow unmanned runs overnight and over weekends. Great for large production jobs with tight timelines.

Speed & Efficiency: We can cut more parts per shift, with minimal setup time. That means lower cost per part and faster delivery.

High-Power Fiber Lasers: With cutting power up to 10kW, our GX-F Series machines make clean, fast work of thick materials, tight radii, and intricate geometries.

Versatility Across Materials & Thicknesses: We can cut a wide range of materials and thicknesses, from thin sheets to thicker metals, making our services adaptable to diverse project requirements.

AI-Driven Quality Control: Each cut is monitored and corrected in real time, reducing the risk of error, waste, or defects.

Scalable Production: Whether you need a one-time production run or ongoing services for large-scale projects, HPM can scale our operations to meet your demands.

Industries HPM Serves

HPM serves a diverse array of markets, providing tailored solutions to meet the unique needs of each industry. From military and data centers to electronics and consumer goods, we leverage our laser-cutting expertise to deliver high-quality products and services that exceed expectations across sectors.

FAQs: Laser Cutting Services Explained

-

Fiber lasers use solid-state technology to cut faster, consume less energy, and handle reflective metals like aluminum and copper more effectively.

-

We cut up to 1” in mild steel, 0.5” in stainless, and 0.375” in aluminum, depending on geometry and edge requirements. Contact us for specialty alloys.

-

Our FMS towers automate raw material loading, part removal, and pallet exchange. This eliminates downtime between shifts and speeds up production without sacrificing quality.

-

Absolutely. We often integrate laser cutting with turret punching, forming, and welding for complex parts requiring both precision cuts and formed features.

Learn More About Laser Cutting

Want to dive deeper into best practices and fabrication strategies? Start here.

-

Turret Punching vs. Laser Cutting: How to Decide Which is Right For Your Project

Not sure whether your part needs a laser or a punch? This blog breaks down use cases, part geometries, and cost considerations to help you make the call.

-

Navigating the Labor Shortage in Metal Fabrication: Strategies for Midwest Manufacturers

See how new laser cutting technologies can help offset labor gaps without sacrificing output.

-

How to Cut Sheet Metal Efficiently and Reduce Material Waste

From intelligent nesting software to edge-to-edge optimization, discover how to cut smarter and lower your material costs.

Get A Quote For Your Metal Fabrication Project

Transform your metal fabrication projects with precision and efficiency through our advanced laser cutting services, seamlessly integrated with our comprehensive capabilities. Contact us today to discuss your needs and request a quote for your complete metal fabrication project.