How to Cut Sheet Metal Efficiently and Reduce Material Waste

Precision matters, but efficiency is where profits are made in metal fabrication. Whether you're working with stainless steel, aluminum, or carbon steel, cutting sheet metal cleanly and with minimal scrap can dramatically lower your production costs, reduce turnaround time, and limit environmental impact. Between rising metal costs and tighter tolerance demands, manufacturers need strategies that boost efficiency without compromising precision.

This guide breaks down the most effective ways to cut sheet metal efficiently and how to minimize material scrap across design, planning, and production.

1. Select the Right Cutting Method for Your Part

Not every job calls for a laser. The cutting method you choose affects material waste, edge quality, cycle time, and scrap rate. Here's a breakdown of the most common technologies:

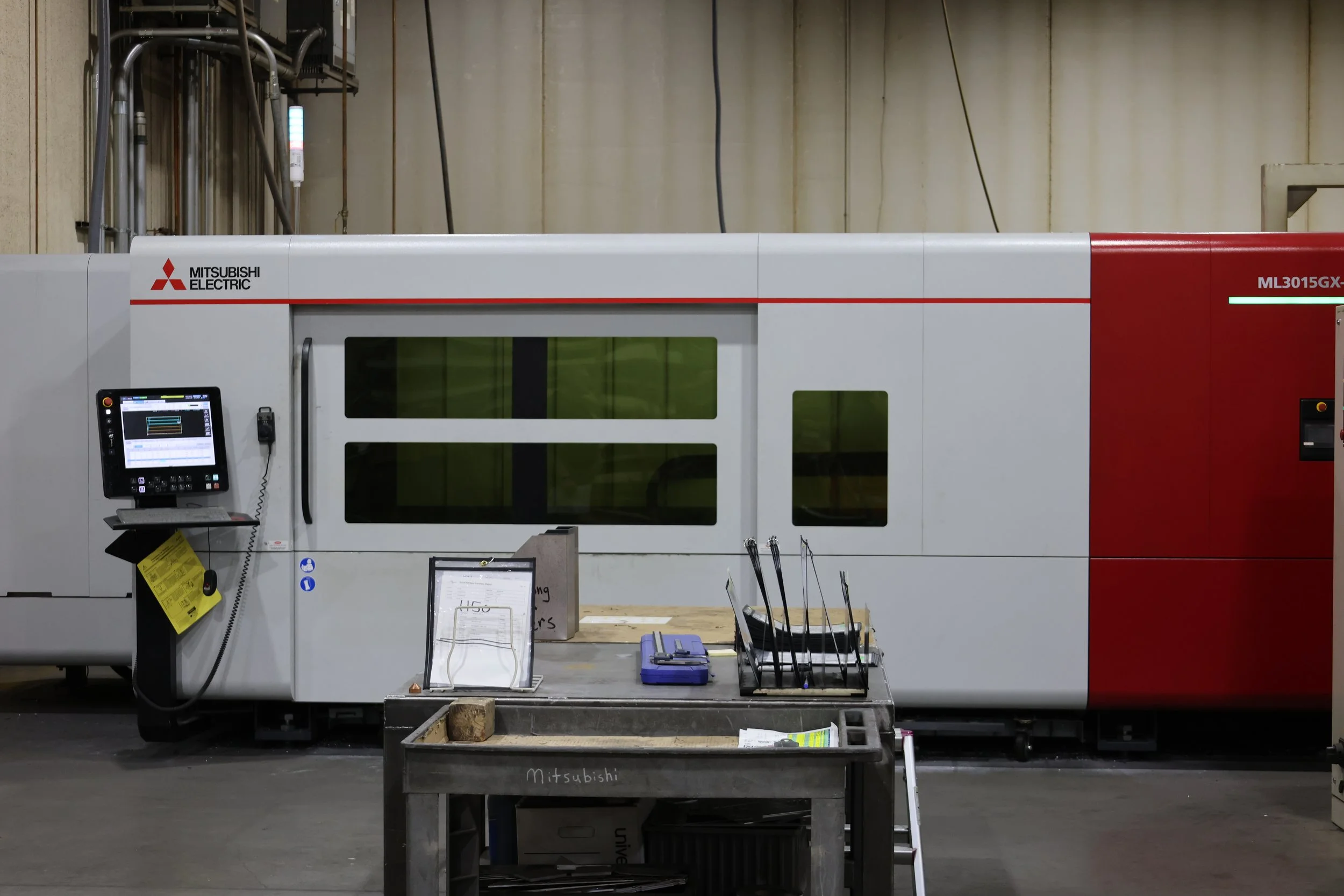

Laser Cutting

Laser cutting offers high precision and a narrow kerf (cut width), good for intricate geometries and tightly nested parts.

Best for: Thin to medium-thickness sheets, fine details, complex shapes

Efficiency: Very high with a narrow kerf and minimal heat-affected zone (HAZ)

Waste: Less than 5% with optimized nesting

Turret Punching

For high-volume production of simple shapes, punching can be the fastest and most economical method.

Best for: Repetitive standard shapes, holes, or embossing 3D formations like taps, extrusions, and countersinks

Efficiency: High for volume; less flexible for complex cuts

Waste: Moderate; it depends on the sheet layout and tool path

Plasma & Waterjet Cutting

While not used as frequently, these methods are useful for specific applications.

Plasma Cutting

Best for: Thicker sheets, lower-precision applications

Efficiency: Faster than laser for heavy stock, but wider kerf increases scrap

Waste: Higher edge cleanup and post-processing

Waterjet Cutting

Best for: Heat-sensitive materials and thick metals

Efficiency: No HAZ; slower than laser

Waste: Low, especially for difficult-to-cut alloys

2. Optimize Your Nesting Strategy

Nesting is the process of arranging parts to fit onto a sheet with minimal leftover material. Advanced nesting software does this automatically, calculating tight layouts that reduce “skeleton” waste. With less leftover frame of the sheet, you can increase your material utilization rate and support batch production and part variation without requiring reprogramming.

Best Practices for Nesting Efficiency

Use dynamic nesting: Adapts to available sheet size and part mix

Group similar parts: Minimizes tool changes and reduces handling time

Factor in kerf width: Accurate nesting needs accurate cut width assumptions

Add common-line cutting: Share borders between parts to cut fewer lines

Modern CAD/CAM software can improve material utilization by up to 15%, especially when cutting complex or nested assemblies.

3. Design with Fabrication in Mind (DFM)

Even the most precise cut can’t fix a part that wasn’t designed with fabrication in mind. That’s where Design for Manufacturability (DFM) comes in.

What Is DFM?

DFM is a methodology that evaluates and refines part designs to make them easier, faster, and cheaper to manufacture, without sacrificing performance or quality. By aligning engineering with real-world production capabilities, DFM reduces the risk of rework, redesign, or excess scrap.

Why It Matters: The Rule of 10

Every design issue that slips through the cracks gets exponentially more expensive to fix downstream. It’s what engineers call the Rule of 10:

A $1 design mistake becomes a $10 fabrication fix

Or a $100 problem if it makes it to final assembly or customer delivery

How DFM Helps Cut Smarter

Optimized Hole Placement: Prevents deformation or burrs during punching

Material Selection: Ensures compatibility with cutting tools and finishing processes

Standardization: Reduces tool changes and enables part consolidation

Secondary Operation Reduction: Eliminates waste from unnecessary handling or rework

DFM Tips to Reduce Scrap

Standardize hole sizes and corner radii to minimize tool changes

Consolidate parts when possible to reduce cut paths

Allow for tabbing or part retention during cutout to prevent drop damage

In short, good design prevents bad cuts. HPM's team of full-time engineers proactively reviews every project to identify waste-reduction opportunities early in the design cycle, where changes are easiest and cheapest to make. This helps eliminate preventable scrap before it hits the shop floor.

4. Track Material Utilization Rate

Knowing your Material Utilization Rate (MUR) is key to identifying improvement areas:

MUR = (Weight of finished parts ÷ Weight of raw sheet) × 100

A well-optimized job should hit 85–95% utilization. Anything below that might mean:

Poor nesting

Inefficient cutting strategy

Design inefficiencies

Unused remnant stock

HPM tracks and reports material usage across all projects, helping clients benchmark and improve their manufacturing efficiency over time.

5. Maintain Equipment and Tooling for Cut Quality

Precision cutting requires properly maintained tools. Even small deviations in tool sharpness or laser focus can create:

Wider kerfs

Burrs or edge deformation

Off-spec parts needing rework

Increased skeleton scrap

HPM follows a strict preventive maintenance program, including punch tool regrinding, laser lens cleaning, and machine calibration logs, so every cut is consistent from the first part to the thousandth.

6. Repurpose and Manage Remnants

Don’t throw away your off-cuts. Track them. Many shops overlook the value of partial sheets that could be reused for:

Prototyping

Short runs

Small brackets or tabs

Non-cosmetic internal components

HPM provides data-driven feedback based on historical runs, helping clients improve both yield and ROI on future orders.

7. Reduce Rework with Tight Quality Control

Scrap isn't always created at the cutting stage. Sometimes it’s the result of nonconforming parts, secondary operations, or miscommunication.

HPM is ISO 9001:2015 certified, with a zero-major finding audit history across 26 BSI assessments. Our system includes:

Real-time inspection

Documented tolerances

First article inspection (FAI)

Process traceability

This level of quality assurance translates into fewer scrapped parts, fewer customer returns, and higher throughput across your entire production line.

Let’s Turn Scrap into Savings

Cutting sheet metal efficiently is about more than using the right tool. It’s about aligning design, material, machine, and method for a leaner, smarter process. At HPM, that’s what we do every day.

Whether you’re designing a new part or trying to reduce costs on an existing one, our team can help you minimize scrap and maximize value. From early-stage engineering to high-precision fabrication, we’ve got the tools, talent, and mindset to help you cut better and waste less. Get in touch with us today.