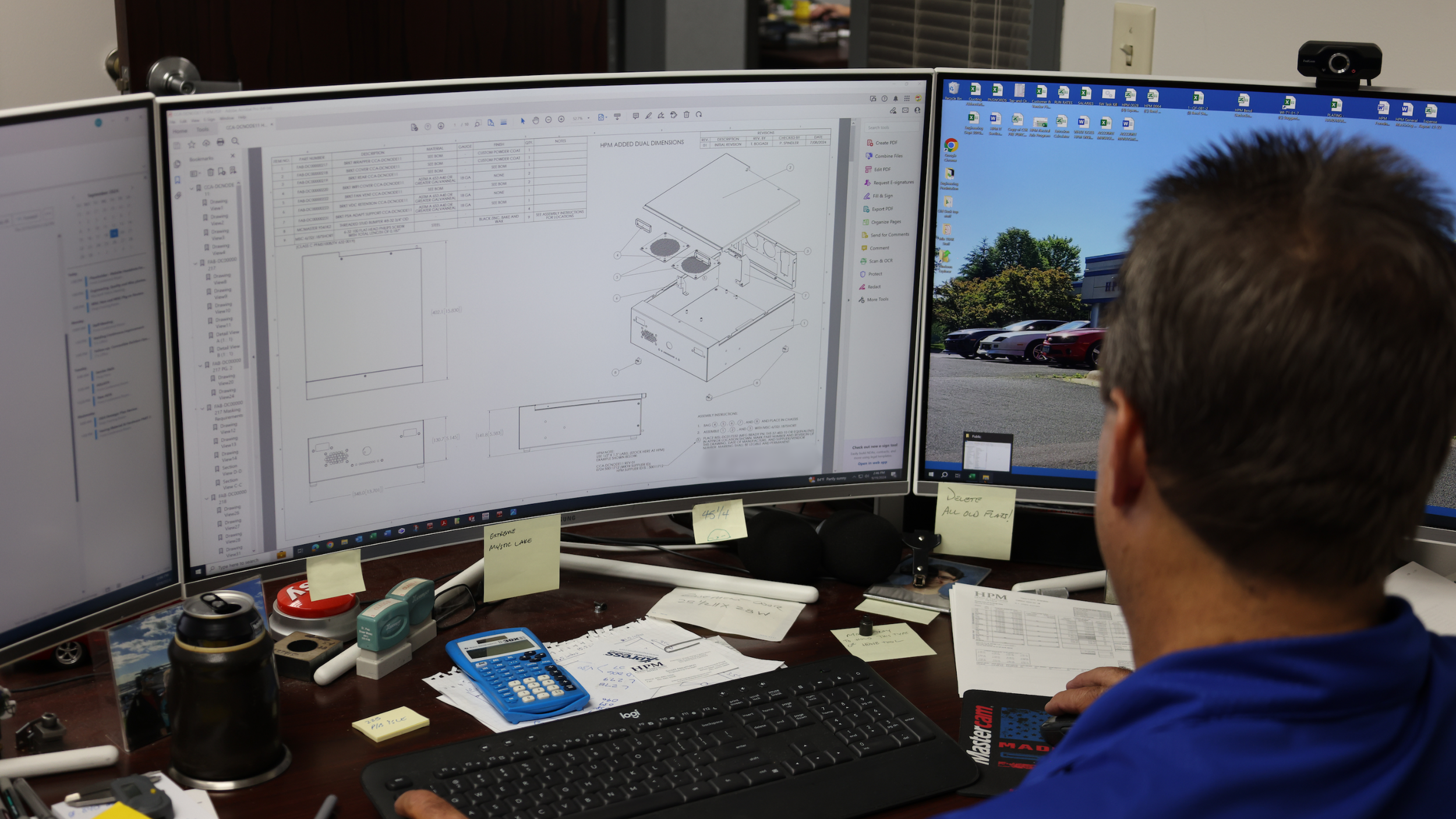

World-Class, American-Made, Metal Fabrication Services

Delivering Excellence in Precision Metal Fabrication for Over 30 Years

Herold Precision Metals fabricates, assembles, and delivers highly engineered, technically difficult, precision metal parts to some of the best companies in the world. We stand out by serving our customers as strategic partners, always adding value to your business through modern fabrication technologies, supply chain management, top-notch engineering, and flawless execution from our team of experts.

Our work may be complex, but our goal is simple:

100% customer satisfaction.

Full Service Metal Fabrication

HPM offers a wide range of metal fabrication services to ensure your project is handled with the utmost precision, quality, and responsiveness. Our state-of-the-art facility and skilled team are equipped to manage projects from initial design to final production. Our services include:

-

Production

Equipped for low through large-scale production, we utilize industry leading fabrication technology and processes to ensure high-quality output and efficiency.

-

Electro-Mechanical Assembly

We offer comprehensive assembly services. From simple components to complex products requiring wiring, testing and certification, put HPM to work for you.

-

Prototyping

Leverage HPM’s dedicated prototype department, deep engineering experience, and robust NPI process. We provide rapid prototyping to help you test and refine your designs and get your product to market faster.

-

Pre-Production

Need design assistance, capability studies, and quality documentation for your validation run? Consider it done.

-

Warehousing

Our 110,000 sqft facility allows us to stage and store your products, ensuring timely and reliable delivery to support your business.

Fabrication Services

Our engineering team is here to provide expert support throughout your project. From design consultation and project management to quality assurance, we offer complete engineering services that ensure your products meet the highest standards.

Early Design Consultation: Collaborate with our engineers from the start to optimize your design for manufacturing and cost efficiency.

Project Management: Benefit from dedicated project managers who ensure every detail is meticulously handled, keeping your project on track.

Prototyping & Testing: Access rapid prototyping services that allow you to refine and validate your designs before full-scale production.

Quality Assurance: Rely on our stringent quality control processes, backed by ISO 9001:2015 certification, to deliver products that meet your exact specifications.

Continuous Improvement: Our engineering team is committed to ongoing innovation, constantly seeking ways to enhance product quality and reduce lead times.

Metal Fabrication Capabilities

Our state-of-the-art facility and extensive range of equipment ensures we can efficiently handle a wide variety of precise metal fabrication needs with market-leading quality.

-

Laser

Wide range of laser cutting ability for various sheet thicknesses.

-

Punching

Utilizes turret punch presses and lasers for efficient stamping and blanking.

-

Forming

Extensive press brake capabilities for a wide range of forming needs.

-

Panel Bending

Salvagnini P4 XE automation gets projects done faster.

-

Hardware Installation

Precision hardware installation using advanced systems.

-

Welding

Certified welding for MIG, TIG, and spot-welding services for various applications.

-

Machining

Provides secondary machining operations, including milling and lathing.

-

Electro-Mechanical Assembly

Offers assembly services up to any required level for complex projects.

-

Deburring & Finishing

Comprehensive deburring and finishing services for all product needs.

Our Commitment to You

At HPM, we measure our success by enabling yours. We believe in transparent, proactive collaboration that elevates every project. Our mission is to deliver not just products, but solutions that drive your success.

The HPM Difference

Our ISO 9001:2015 certification guarantees that our processes and products meet the highest standards of quality.

Quality Assurance

Our team undergoes rigorous training to stay updated with the latest industry practices and technologies.

Experienced Team

We invest continuously in advanced technology to provide precise and reliable metal fabrication solutions.

Cutting-Edge Technology

We view our clients as strategic partners and are committed to adding value to your business through transparent collaboration and exceptional service.

Customer-Centric Approach