Designing for the Elements: Why Real Engineers Think Beyond the Print

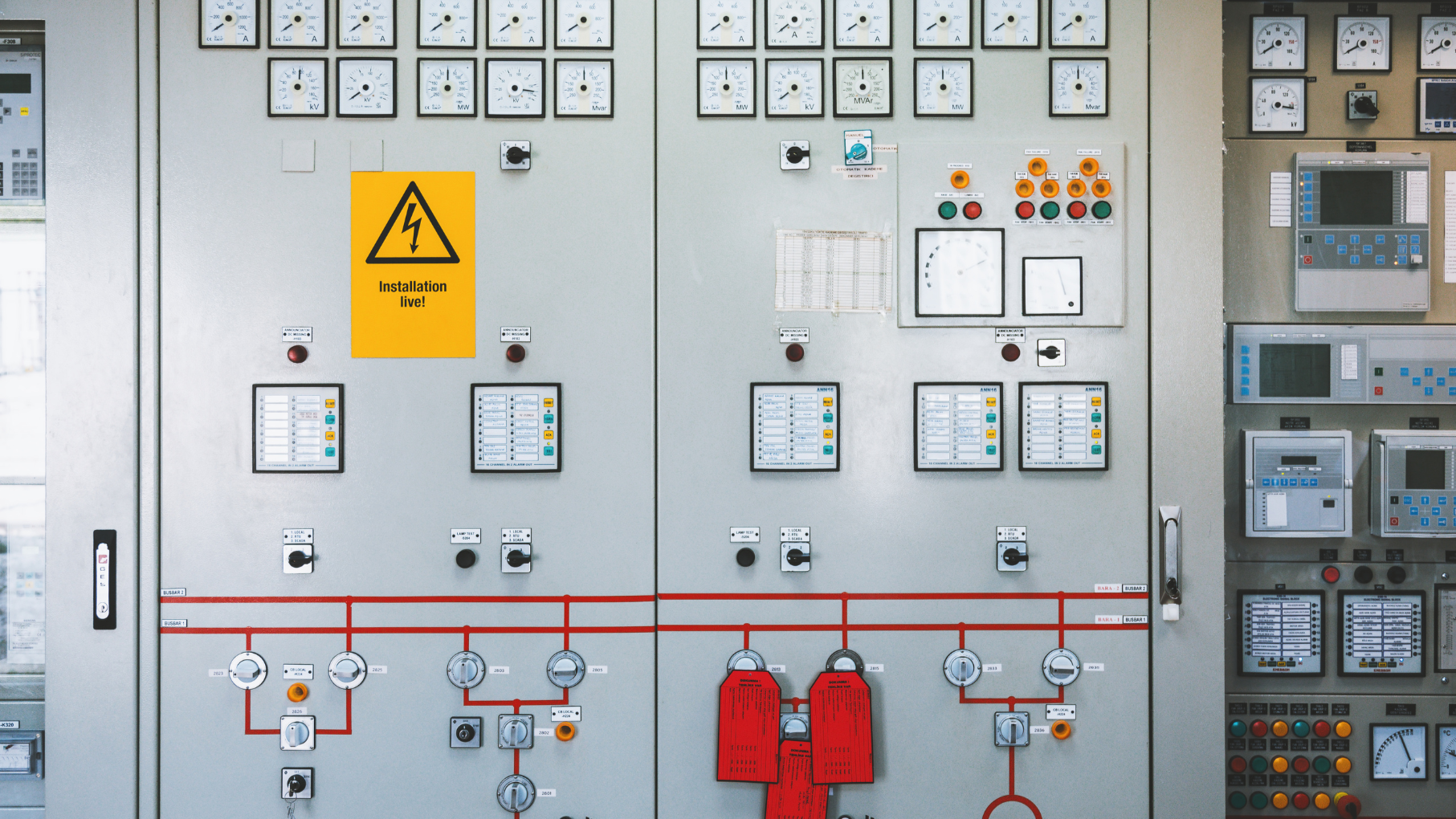

A precise, two-dimensional technical print specifying tolerances, materials, and geometry is the foundation of manufacturing. But for products destined for the real world, like on a factory floor, in an arid climate, or at an electrical utility box, relying solely on print is a recipe for failure.

Our engineering team operates with a critical understanding that most original equipment manufacturers (OEMs) underestimate environment-driven failure modes. They design for the specified dimensions, but neglect the inevitable forces that will cause premature degradation.

If your supplier isn’t thinking about the elements, your product won’t survive them. This blog explains why you need a strategic partner that delivers true environmental design engineering, where you engineer around conditions, not just specifications, so your product is built for survival.

Neglecting Design for the Environment: 5 Common Costs of Failure

The Design for Environment (DfE) principle is often misinterpreted as focusing solely on sustainability and recycling. While important, DfE, in the context of critical component manufacturing, really starts with product survival. A failure caused by a single overlooked environmental factor, such as a burst capacitor due to overheating or a short circuit from moisture ingress, can cost millions in recalls, service visits, and reputational damage.

Our environmental design engineering proactively addresses the "Big 5" threats through material and geometry choices in sheet metal fabrication.

1. Thermal Management: Controlling the Invisible Killer

Heat is the single greatest enemy of electronics. Even if a component is rated for high temperatures, the buildup of heat inside a sealed metal enclosure can create a microclimate that exceeds thermal limits. If internal temperatures exceed the operating threshold, the lifespan of PCBs, batteries, and power supplies can be reduced by up to 50%.

Our engineers incorporate thermal management design strategies into the sheet metal geometry itself. This involves optimizing passive cooling through strategically placed vents, designing mounting patterns that enable forced-air exchange, and recommending materials (such as aluminum grades 5052 or 6061) with excellent thermal conductivity.

2. EMI/EMC Shielding: Protecting the Signal

In industrial, military, and data center environments, electronic products must protect their sensitive components from external electromagnetic interference (EMI) while also preventing their own emissions from disrupting nearby equipment (EMC). The threat here is stray electromagnetic energy that can cause data corruption, signal loss, or compliance failures.

An effective EMI shielding design is built into the enclosure structure. This requires ensuring a continuous electrical path. We design flange connections that eliminate RF leakage gaps and specify the precise application of conductive gasketing. The choice of material (steel for magnetic shielding, aluminum for general conductivity) is based on the specific frequency threat.

3. Dust and Moisture Protection (IP Rating)

For any product installed outdoors or in dusty/wet industrial settings, water- and dust-resistance is non-negotiable. If protection is inadequate, the threats are corrosion, short circuits, and mechanical seizure caused by water vapor, rain, or particulates.

We collaborate with your team to design sheet-metal enclosures to meet specific Ingress Protection (IP) rating standards. This involves reducing the number and length of seams (favoring a formed box over a welded one, where feasible), designing integrated drainage channels and drip edges, and specifying mounting holes and access points for optimal gasket compression. We ensure every penetration maintains the enclosure’s integrity.

4. Corrosion & Material Degradation

The material must match the severity of the environment AND the load requirement. Salt spray, humidity, and chemical exposure can quickly lead to material failure, resulting in rusting, chemical etching, and weakening of structural components.

Our engineers guide the selection of materials such as Galvanneal for moisture resistance, different grades of stainless steel (316 for higher corrosion resistance) for harsh chemical processing, and specialized chemical conversion coatings prior to finishing.

5. Mechanical Integrity (Shock and Vibration)

If your enclosure is mounted on heavy machinery or transport equipment, it must resist dynamic forces that can cause loosening and metal fatigue. The threat is loose fasteners, welds fatiguing, and components shifting out of alignment.

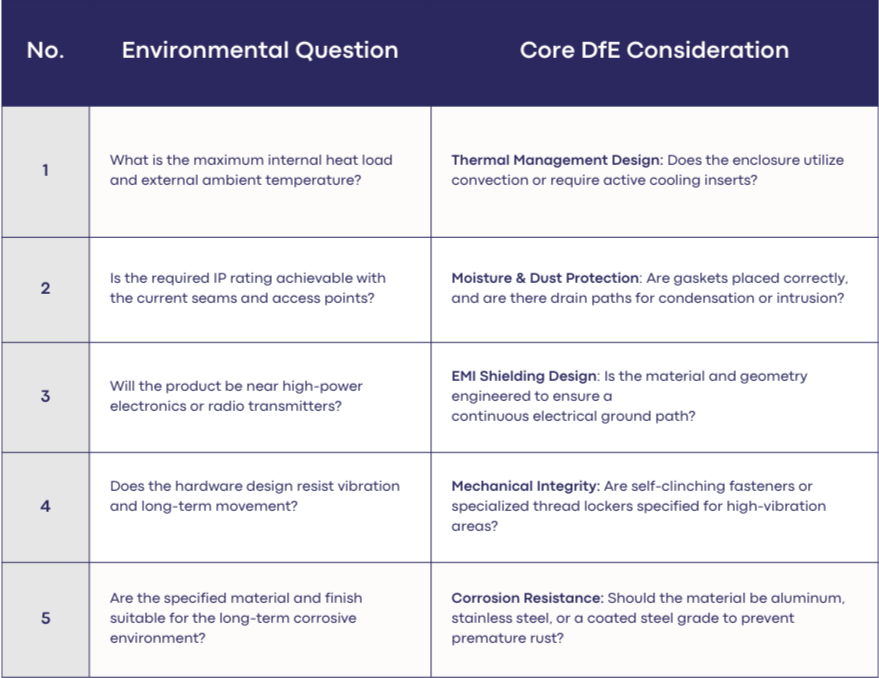

The 5 Environmental Questions Every Engineer Should Ask

Before you finalize a drawing and submit it for a quote, HPM encourages you to use this framework to apply a preliminary product failure analysis to your design:

Partner with HPM's Design Engineering Team

We treat the environment as a set of non-negotiable specifications. Our engineering expertise accounts for real-world forces to ensure your design is built to withstand and succeed.

Don't just manufacture your design. Engineer its survival. Explore our engineering capabilities and contact HPM's engineering team today to ensure your product is designed for its long-term environment.