Mastering Sheet Metal Assembly: 5 Essential Techniques and Applications

Sheet metal assembly is often one of the final steps in fabrication, where precision engineering meets practical function. Whether you’re creating enclosures, control panels, or brackets, the joining method must align with performance demands, materials, tolerances, and production volume.

We specialize in high-mix, tight-tolerance sheet metal assemblies, offering everything from mechanical fastening and welding to full electro-mechanical integration. This blog breaks down the core techniques used in fabrication, when each one makes the most sense, and how precision assembly contributes to product quality and lifecycle performance.

What Is Sheet Metal Assembly?

Sheet metal assembly involves joining two or more fabricated parts into a functional unit. It’s not a one-size-fits-all process. Depending on the design requirements, material characteristics, and final application, assembly may require threaded fasteners, press-fit PEM hardware, spot welds, rivets, or a combination of joining methods.

The assembly phase typically follows operations like laser cutting, punching, or bending and includes quality-critical steps such as alignment, fastening, and torque-controlled joining. For more complex builds, it also provides wire routing, component installation, labeling, and final testing as part of electro-mechanical assembly.

Assembly as Part of Design for Manufacturing

Effective sheet metal assembly starts at the design table. Through early collaboration, our team helps engineers apply Design for Manufacturability (DFM) and Design for Assembly (DFA) principles, recommending fastening methods and tolerances that reduce cost and improve build efficiency.

For example, switching from tapped holes to PEM inserts or standardizing panel thicknesses can simplify tooling and shorten lead times. These small decisions make a big difference, especially when scaling from prototype to production.

5 Key Sheet Metal Assembly Techniques

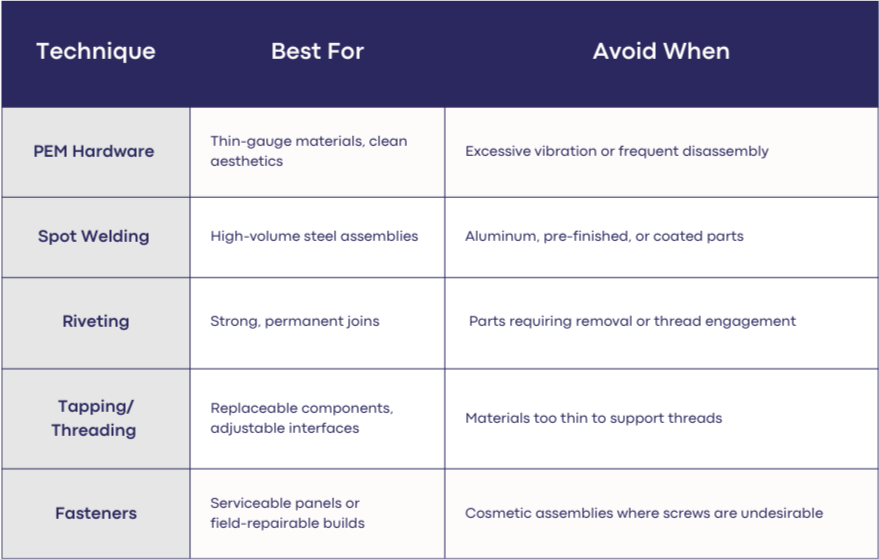

Below are the most commonly used techniques in modern sheet metal fabrication, with notes on typical applications, advantages, and key considerations.

1. PEM Hardware Installation

PEM or self-clinching hardware is a go-to solution for joining sheet metal parts where thread strength, durability, and repeatability matter. Press-fit fasteners like nuts, studs, and standoffs are installed using a cold-forming process that displaces metal into undercuts, creating a secure and flush-mounted fit without welding or adhesives.

Use Cases:

Electronics enclosures

Subpanels requiring PCB mounting

High-density assemblies where welding isn’t practical

Advantages:

No welding heat distortion

Flush appearance

Consistent installation torque

2. Spot Welding

Resistance spot welding is ideal for joining overlapping steel sheets without the need for filler metal. It uses heat generated by electrical resistance and pressure from electrodes to create a strong, localized weld.

Use Cases:

Structural brackets

Sheet metal enclosures

Galvanized assemblies

Advantages:

No hardware costs

Fast cycle times

Excellent shear strength

Considerations: Spot welding is not well suited for painted/coated parts without additional prep.

3. Riveting

Rivets, especially blind or “pop” rivets, provide a mechanically robust and vibration-resistant method for permanent fastening. Unlike screws or bolts, they don’t rely on internal threads, making them ideal for thin-gauge materials.

Use Cases:

Hinged access panels

Aerospace and transportation assemblies

Applications where disassembly is not required

Advantages:

Secure hold in single-sided access areas

No threading or torque requirements

Better suited for dynamic loading than some adhesives

Pro Tip: In some assemblies, we’ll recommend a mix of rivets and PEM fasteners or welding to balance load distribution and serviceability.

4. Tapping and Threading

Threaded holes are frequently used in brackets and enclosures where replaceable or adjustable components must be installed. There are several ways to achieve threaded features in sheet metal: tapped holes, self-clinching fasteners, or extruded holes followed by threading.

Use Cases:

Mounting brackets

Chassis components

Adjustable mechanical interfaces

Advantages:

Allows for screw removal and reinstallation

Reduces part count by eliminating extra fasteners

5. Fasteners and Screws

Machine screws, sheet metal screws, and thread-forming fasteners are widely used in assemblies that require maintenance access or part replacement. Paired with tapped holes or PEM nuts, they allow for disassembly and field servicing.

Use Cases:

Enclosures with service panels

Electro-mechanical subassemblies

Products requiring modularity

Advantages:

Easy to disassemble

Off-the-shelf hardware

Repeatable torque control

Tip: We often recommend torque specs and thread-locking solutions during design review to reduce vibration-related failures.

Matching Technique to Application

The “right” assembly method depends on multiple factors: material thickness, expected loads, serviceability, production volume, and downstream requirements like painting or powder coating.

Here’s how we typically guide selection:

From Rivets to Welds: Solving Assembly Challenges in the Real World

A great example of assembly strategy in action comes from a recent medical industry project. A customer approached us with a prototype enclosure that relied on welding, to hold its panels together. While the design worked in theory, it introduced several issues in practice: inconsistent alignment, visible fastener heads, and a complex multi-step assembly process.

We reviewed the design through a DFA lens and recommended switching to a welded assembly approach. This change eliminated the need for external hardware, improved part alignment, and created a smoother, more polished final product. Our team then fabricated and welded the revised design, followed by post-processing and powder coating.

The results?

Fewer parts and reduced labor time

Improved cosmetic appearance with seamless exterior panels

Stronger structural integrity for repeated handling and sterilization

This project reflects what we do best: helping customers optimize their assemblies for performance, manufacturability, and scale without compromising on quality or function.

Precision Assembly, Built In

Assembly may be the final step in sheet metal fabrication, but it’s also one of the most critical. Done right, it enhances structural integrity, minimizes field issues, and reduces your production timeline.

We don’t treat assembly as an afterthought. It’s part of a larger quality system that includes material traceability, process control, and documented inspection at every step.

Explore our certified electro-mechanical assembly services, or contact us to learn how we can support your next project from cut to complete.