Your Supplier Shouldn’t Be the Reason You Miss ISO Audits

For many manufacturers, passing an ISO audit is a requirement for keeping business. But even when your own quality systems are airtight, a weak link in your supply chain can cost you compliance.

Supplier performance is one of the top reasons organizations fail ISO 9001 audits. A late material cert, an unverified sub-supplier, or a missing corrective-action report can all trigger a non-conformance. And when that happens, the auditor doesn’t blame your supplier; they write you up.

In this blog, we’ll break down the most common supplier-related causes of ISO audit failures, what auditors are really looking for when evaluating supplier control, and how partnering with an ISO-certified manufacturer like Herold Precision Metals helps you stay audit-ready from documentation to delivery.

When Good Suppliers Cause Bad Audits

Auditors look for control, documentation, and consistency across your supply chain. Under ISO 9001 Clause 8.4, you’re responsible for verifying that external providers meet requirements for products, processes, and services.

That means every certificate, every inspection report, and every corrective action tied to your suppliers becomes part of your audit trail. When a vendor fails to document materials, skips inspections, or delays CAPA closure, it creates gaps your quality team can’t defend.

Some of the most common supplier-related findings include:

● Missing or outdated certificates of conformance

● Incomplete inspection records or uncontrolled revisions

● Unverified corrective actions for recurring defects

● Lack of performance metrics for supplier evaluation

These findings reveal patterns of risk that auditors are trained to spot. Knowing the warning signs before they appear on an audit report can help you strengthen supplier oversight and protect your certification.

Five Supplier Red Flags That Can Sink an Audit

These are the kinds of problems auditors notice immediately. They’re also the issues that often accumulate quietly in the background, unnoticed until audit day. Each one points to a breakdown in supplier control or documentation that could put your certification at risk.

1. Incomplete Documentation

Auditors expect full traceability from material certifications and inspection reports to revision histories and operator records. When suppliers fail to provide or maintain that documentation, it suggests a lack of process control. Even a missing material cert or an outdated inspection sheet can be enough to trigger a non-conformance finding.

2. Recurring Non-Conformities

A one-time defect might not raise concern, but repeated issues without a verified corrective action plan indicate a systemic failure. Auditors look for evidence that suppliers perform root-cause analysis, implement corrective measures, and confirm effectiveness. Without that proof, the assumption is that problems aren’t being resolved.

3. Poor Communication

When a supplier doesn’t respond quickly to quality alerts, material changes, or document requests, it creates blind spots that auditors can’t overlook. Lack of communication means you can’t verify compliance in real time, which undermines the

“control of external processes” clause in ISO 9001. Consistent updates, responsiveness, and documented correspondence are key indicators of supplier reliability.

4. Unverified Sub-Suppliers

Your responsibility doesn’t end with your direct suppliers. Auditors will expect you to demonstrate visibility and control across the entire supply chain. If a Tier 2 or Tier 3 vendor can’t provide traceable records for their own partners, it creates a compliance gap that flows upstream to you. Risk-based evaluation of all sub-suppliers (even those providing small components) is essential.

5. No Continuous Improvement

ISO audits favor proactive improvement over just reactive fixes. Suppliers should be able to show ongoing performance monitoring, KPI reviews, and process enhancements. When a vendor treats quality as a static requirement rather than a living system, it signals stagnation and auditors notice.

By identifying and addressing these red flags early, manufacturers can strengthen supplier oversight and enter every audit with confidence that their partners are as disciplined as they are.

How HPM Keeps You Audit-Ready

We operate with Tier 1 discipline even when we’re Tier 2 on the PO. Our systems, documentation, and communication practices help customers avoid supplier-driven audit failures before they start.

Certified Quality Management System (ISO 9001:2015)

HPM’s quality program is certified and audited annually to align with ISO 9001:2015 standards for manufacturing, traceability, and customer satisfaction. Our internal audits and management reviews ensure that procedures remain compliant, up to date, and effective.

Layered Inspection Processes

Every project undergoes pre-production, in-process, and final inspections. This structured approach eliminates variation, verifies critical dimensions, and provides documented proof of conformity.

Full Traceability and Documentation

Manufactured parts carry a digital record (material certs, lot numbers, operator IDs, and inspection results) stored for quick retrieval during audits or supplier reviews.

Formal CAPA and Root Cause Verification

When an issue occurs, our CAPA process tracks it from investigation to closure. Every corrective action includes root-cause validation and effectiveness checks, ensuring real fixes instead of temporary patches.

Supplier Oversight and Risk Management

HPM holds its own suppliers to the same standards. We maintain a risk-based evaluation system that audits vendors, tracks on-time performance, and verifies quality certifications, protecting your compliance chain from start to finish.

A Partnership That Passes Every Test

Audit success starts long before inspection day. It begins with how your partners operate.

HPM’s collaboration begins early in the process with Design for Manufacturability (DFM) reviews and engineering consultations that help identify potential issues before production starts. During fabrication and assembly, our project managers keep you informed through consistent communication, inspection updates, and proactive scheduling adjustments.

That transparency builds the audit trail you need to show control, communication, and continuous improvement at every level of your supply chain. Because when your supplier operates like a Tier 1 partner, you’re always one step ahead of the auditor.

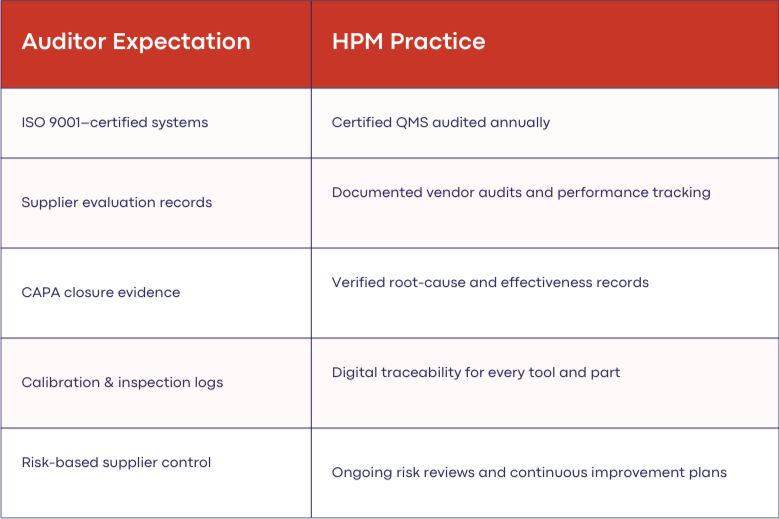

What Auditors Want to See (And How HPM Delivers)

Protect Your Certification, Partner with HPM

Your next ISO audit shouldn’t depend on whether a supplier followed through. At Herold Precision Metals, we make sure it never does. Our ISO-certified quality systems, disciplined documentation, and transparent communication help contract manufacturers stay compliant, confident, and competitive. Explore our contract manufacturing partnerships or request a quote to get started on fabrication projects right away.