Don’t Send Us a Print. Send Us a Problem.

Some shops want a spec sheet and a PO. But we do things differently. We want your biggest headache.

If you’re wrestling with tricky tolerances, frustrating assemblies, or prototypes that aren’t quite right, we’d rather roll up our sleeves and solve the root problem than blindly quote a print. That’s because we’re your engineering partner from idea to execution.

Skip the Quote-Only Phase: Why Early Problem-Solving Matters

We know how it usually goes: You email a PDF and wait for pricing. But what if that print includes a bend radius that won’t work with your material? Or a hole pattern that’s too tight for your intended application?

That’s where our Design for Manufacturability (DFM) expertise comes in. Before we cut a single part, we’ll walk through your CAD file, identify risks, and collaborate with your engineers to optimize for:

Material thickness and formability

Tool access for punching or bending

Hole-to-edge and hole-to-hole distances

Fastening and assembly strategies

Our goal isn’t to re-engineer your part but to make sure you don’t spend time and money building something that won’t function or scale.

What Happens When You Redesign for Real-World Assembly?

Sometimes, what works in CAD doesn’t work in the field. We once helped a medical customer with a stainless steel bracket that passed inspection in isolation but failed when mated with other components. After reviewing the design, we recommended changes that reduced the number of formed features and made welding more repeatable.

That’s what turned into this medical manufacturing success story. The client reduced downstream assembly time and saw improved consistency across batches. Not because we quoted the part, but because we questioned the design.

Early Prototypes, Fast Iterations, Better Outcomes

Getting involved early also accelerates prototyping. With our rapid prototype services, we help you move from concept to first article faster, while avoiding common missteps, such as overengineering a bracket that never required tight tolerances in the first place.

Need a test run in aluminum before switching to steel? Want to try a riveted version before committing to welding? We’ve been through that cycle hundreds of times and can recommend cost-effective paths to production.

HPM’s dedicated Prototype department.

Assembly Complexity? Bring It On.

We don’t shy away from builds with multiple steps and parts. In fact, that’s where we shine.

Our assembly capabilities include riveting, PEM installation, hardware sourcing, and even full box builds. But we go beyond just putting parts together. We think critically about how design impacts build sequence, quality control, and cost.

When you bring us in early, we’ll flag:

Which tolerances are driving cost without improving fit

How your part will behave during forming or welding

What can be consolidated to reduce part count or assembly steps

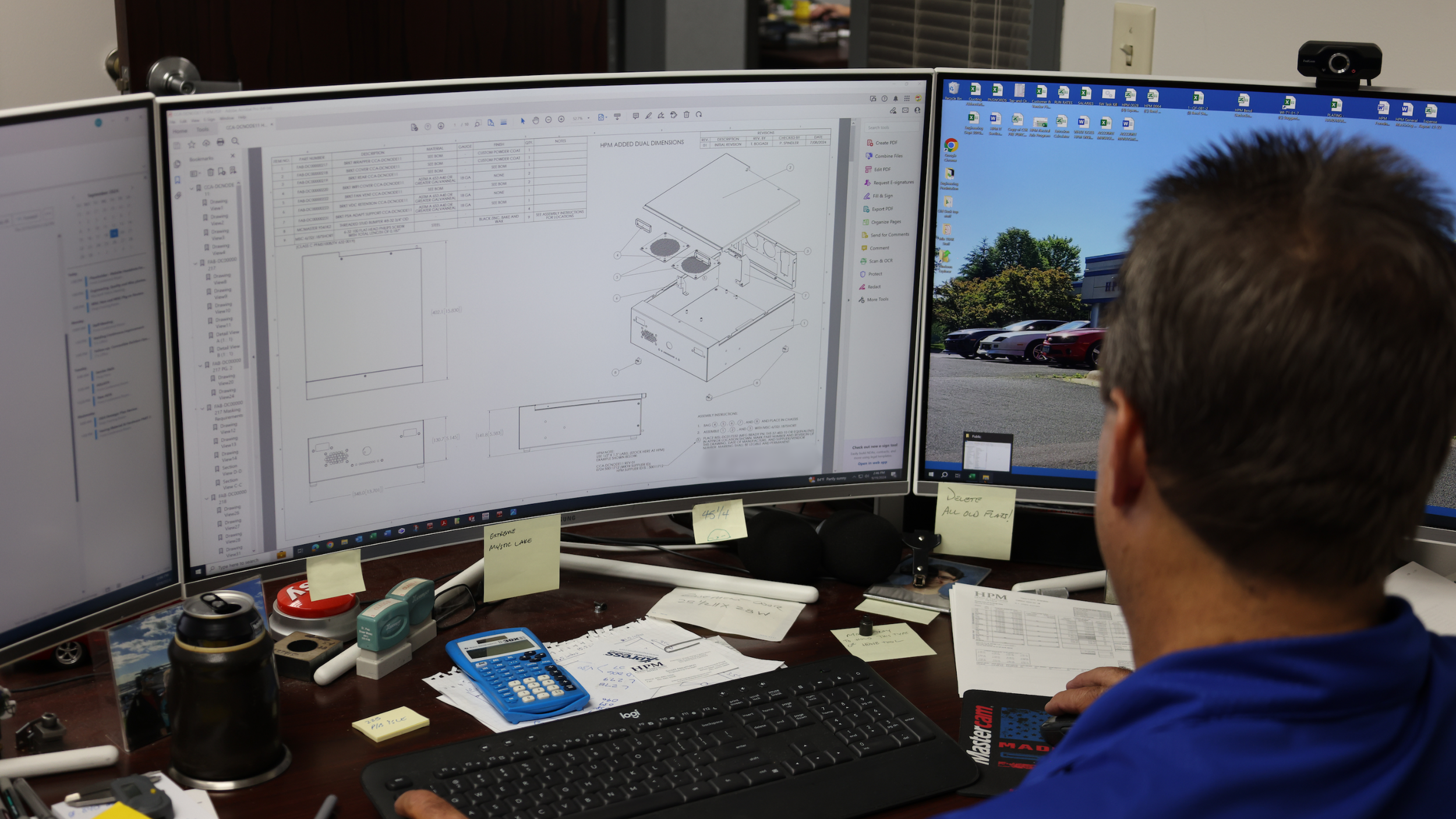

Our account managers and engineers work side-by-side with the shop floor to ensure your part is fabricated, assembled, and inspected with the end use in mind.

Quality Starts Before the First Cut

Don’t wait until the First Article Inspection Report (FAIR) to discover your CAD file had hidden issues. Our quality assurance process starts well before production, often during the quote and review phase.

We use laser scanning, inspection reports, and FAI documentation to verify every part meets your requirements. But more importantly, we design quality into the process by addressing risks up front.

Partner with Engineers, Not Just Fabricators

If you just want a part made to spec, plenty of shops can do that. But if you want a smarter, smoother path from design to delivery, you need a partner who asks questions, challenges assumptions, and sweats the small stuff before it becomes a big delay.

At Herold Precision Metals, we don’t just take orders. We take ownership. Start your next project with a conversation.